Drum Solenoid Interface for Tap-Tempo Metronome

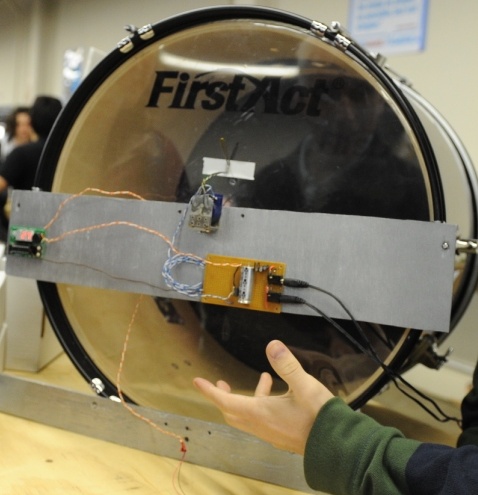

If you stopped by our table at the Maker Faire, you got to play around with our big drum demo of the Tap-Tempo Metronome. Lots of people had questions about how we drove the solenoid for the drum striker, so we decided to write it up once we got back home.

We added an external piezoelectric element to set on the bench top, making it easier for kids to reach. We simply soldered this external piezo element to the same pads as the Tap-Tempo Metronome’s built-in piezo element. Here’s the large piezo we used.

For the drum striker, we used an electromagnetic solenoid, which consists of a coil of wire wound around a movable metal core. When current is sent through the coil, the metal core moves a short distance. Unfortunately, the pins on a microcontroller are relatively weak, meaning that they can only supply 20-40 milliamps (mA) of current, compared to the 1 amp draw of our solenoid. This means that we can’t directly connect the microcontroller to the solenoid, as not enough current would be supplied. The usual solution to this drive strength problem is to use a transistor as a switch.

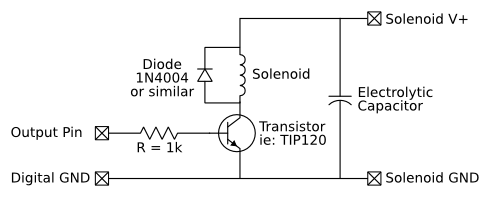

Here’s a very common way to drive a large inductive load from a microcontroller. Since the solenoid requires a higher supply voltage, 12v in our case, we need to account for the extra power supply. In this circuit, we use a transistor that can easily handle the current through the solenoid (1A). We used a TIP120, which is a kind of power transistor that can be treated like a NPN bipolar junction transistor (BJT) and can handle up to 5 amps of current, more than enough for our 1A solenoid.

While this circuit is very common, the diagram is based on an example diagram from the Arduino Playground (PDF). When the output pin from the microcontroller is driven high, the path between the top and bottom terminals of the transistor are connected, allowing current to flow through the solenoid. When the output pin is driven low, no current flows through the transistor, stopping the solenoid. The large electrolytic capacitor is very important, as it is used to help supply the large current draw of the solenoid. The capacitance should be at least 1000 uF. The resistor is used to limit current through the pin.

While this circuit is very common, the diagram is based on an example diagram from the Arduino Playground (PDF). When the output pin from the microcontroller is driven high, the path between the top and bottom terminals of the transistor are connected, allowing current to flow through the solenoid. When the output pin is driven low, no current flows through the transistor, stopping the solenoid. The large electrolytic capacitor is very important, as it is used to help supply the large current draw of the solenoid. The capacitance should be at least 1000 uF. The resistor is used to limit current through the pin.

One very important part of this circuit is the protection diode. A diode is a special piece of silicon that only conducts electricity in one direction. Solenoids, relays, and motors are essentially just big coils of wire that generate magnetic fields when current is flowing through them. Sometimes a coil of wire is called an inductor. When the current stops flowing through the coil, the magnetic field tries to keep the current flowing, and actually pushes more current through the wires, a phenomenon called inductive kickback. This current push can be dangerous to the transistor and microcontroller, so we have to add the protection diode.

Once you have this circuit constructed, you need to make some slight modifications to the Tap-Tempo Metronome:

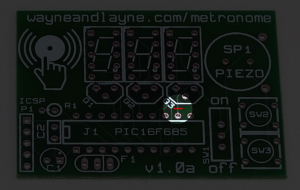

- Update the firmware to version 1.15. This firmware beeps and displays “15” on startup, and generates the necessary pulses on pin 12 for each beat. If you have access to a PIC programmer, you can update your metronome with the new firmware available from the download page. We are working to upgrade our online marketplace to allow us to sell updated PIC microcontrollers. Check back soon for more details.

- The output pin, pin 12, is normally connected to the unused decimal point LEDs in the seven-segment displays. We can easily disconnect it by cutting a trace with a sharp knife, such as an X-Acto knife.

Carefully cut the trace by moving the blade over it multiple times. Be careful not to cut the adjacent traces. Keep cutting until you can see the gap between the two sides. If you have a multimeter, you can make sure that there is no continuity between pin 12 on the chip and pin 7 on the seven-segment displays.

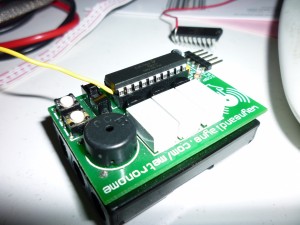

- Connect a wire to pin 12 on the chip. You can do this easily by taking a length of breadboard wire and forming a tiny loop in one end. Remove the chip from the socket, and place this loop of wire into pin 12’s spot.

If you do it right, you can push the chip back into the socket and trap the wire there. It might look something like this when you’re all finished:

See what happens when we connect a vibration motor, making for an even more “tactile” experience!

Trackbacks and Pingbacks